Henan Changxing Refractory Material Co.,Ltd.

Industry Dynamic

Providing Free technical guidance & Best Products

Emai: info@cxrefractories.com

Erosion mechanism of submerged nozzle

The immersion nozzle is one of the three major components in continuous casting and serves as a critical functional material with an indispensable role. It is positioned between the ladle and the mold during the continuous casting process.

1. Introduction to Immersion Nozzles

The fundamental requirements for submerged nozzle materials include excellent resistance to molten steel erosion, strong resistance to slag corrosion, good thermal shock resistance, and low susceptibility to nozzle clogging. As a crucial component of the “three major parts” in continuous casting, submerged nozzles have undergone continuous development and upgrades—from fused quartz nozzles to aluminum-carbon nozzles, and finally to the current aluminum-carbon-zirconium-carbon composite nozzles. Due to their superior resistance to slag erosion and thermal shock, aluminum-carbon-zirconium-carbon composite submerged nozzles are widely adopted and have become the mainstream type.

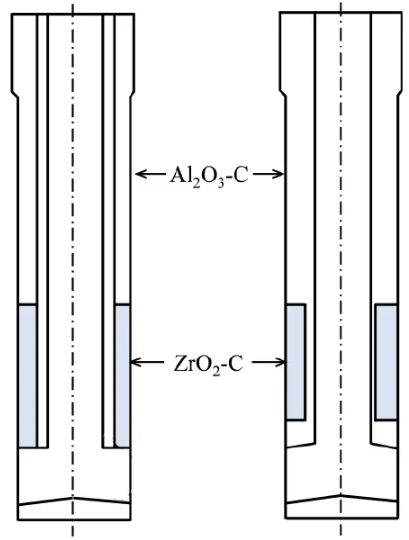

As shown in Figure 2, this is an Al₂O₃-C/ZrO₂-C composite submerged nozzle. The main body uses Al₂O₃-C material, while the slag line position employs ZrO₂-C material. The slag line area is prone to erosion. Zirconia is selected for this section due to its chemical stability, minimal reactivity with other substances, and properties such as a high melting point (2700°C), high resistivity, high refractive index, and low thermal expansion coefficient. These characteristics effectively mitigate erosion issues.

Al₂O₃-C/ZrO₂-C Composite Immersion Nozzle Multilayer Structure

2. Erosion Mechanism of Immersed Nozzles

2.1 Overall Erosion of Submerged Nozzles in Molten Steel

The submerged nozzles currently used in continuous casting production technology are primarily aluminum-carbon-zirconium-carbon composite nozzles. The main body is aluminum-carbon, while the slag line section is zirconium-carbon. Therefore, the erosion of submerged nozzles in molten steel refers specifically to the corrosion of the aluminum-carbon nozzle by molten steel. Compared to the harsh environment at the slag line where the material interfaces with molten steel, slag, and refractories, erosion of the submerged nozzle's refractory material in molten steel is significantly less severe. It primarily involves carbon oxidation and erosion caused by the impact of molten steel flow. The erosion rate at this location is extremely slow and does not constitute a critical factor affecting the nozzle's service life.

2.2 Erosion of Submerged Nozzles at the Steel-Slag Interface

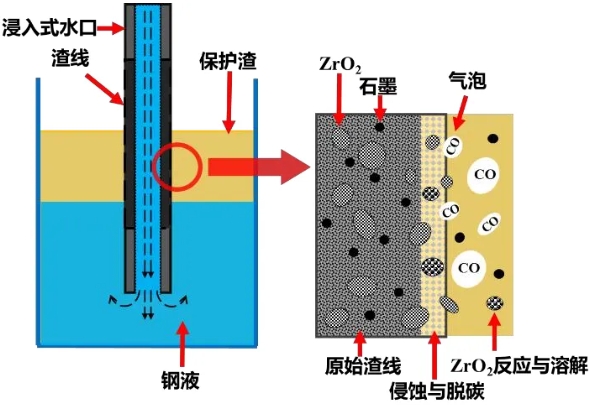

The submerged nozzle's slag line region, situated at the triple-phase interface of steel-slag-refractory material (as shown in Figure 3), experiences localized erosion due to its harsh operating environment. This occurs because during continuous casting, prolonged exposure to high temperatures triggers complex physicochemical reactions at the interfaces between steel, slag, and nozzle refractories, leading to erosion. These processes primarily include: - Structural alterations and defect formation due to crystal destruction - Slag penetration - Formation and dissolution of solid solutions - Sintering and recrystallization - Decomposition of various system components within the slag and melt.

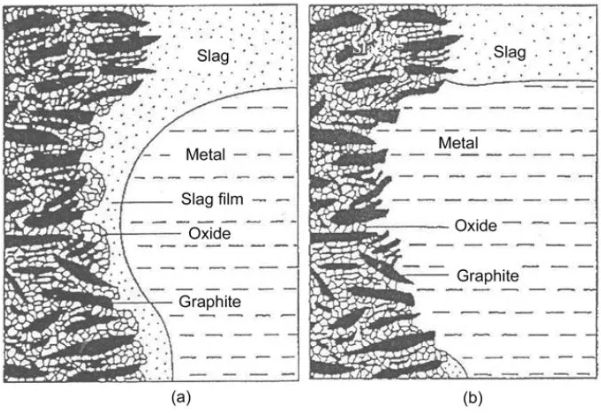

Regarding the localized erosion mechanism at the slag line region, numerous scholars have published detailed research reports. Mukai et al. elaborated on its erosion mechanism, proposing that as shown in Figure 4: (a) depicts the protective slag entering the space between the nozzle refractory wall and molten steel when the steel-slag interface is descending, forming a slag film on the nozzle wall surface. (b) depicts the ascending phase of the steel-slag interface. Upon contact between graphite and molten steel, the molten steel rapidly oxidizes or dissolves the carbon within the nozzle refractory material.

Slag Line Erosion Process in Continuous Casting

2.3 Erosion of Immersed Nozzles at the Slag-Melt Interface

Even though the mold slag has poor wettability on graphite, it can slow down the erosion of the nozzle refractory to a certain extent. However, due to the presence of pores in the nozzle refractory itself, pores will also form after carbon oxidation. At the same time, the various physical and chemical properties of the mold slag have good wettability on the nozzle, which will also cause serious erosion at the nozzle slag line, affecting the service life of the submerged nozzle and thus affecting the smooth operation of multiple furnace continuous casting. During the continuous casting process, the vibration of the crystallizer will cause relative movement between the slag and the submerged nozzle, and the slag film formed on the nozzle wall will also undergo corresponding movement. This movement mode is the same as the slag film movement mode proposed by Kusuo Mukai et al.

Schematic Diagram of the Erosion Process of Composite Refractory Materials

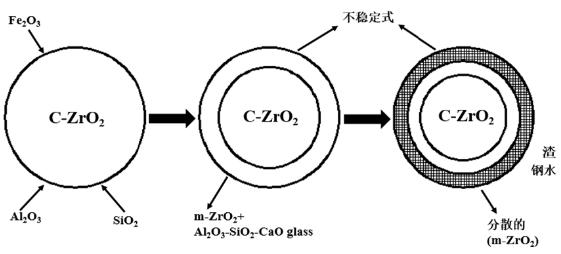

Whether in localized erosion at the molten steel-slag interface or the nozzle-slag interface, changes in the ZrO₂ aggregate within the nozzle refractory material also influence the nozzle's erosion resistance to some extent. During heating of the submerged nozzle, gases produced by the reduction reaction of oxides in the graphite powder react with CaO to form a liquid phase. This causes zirconia to transform from cubic to monoclinic crystals, leading to the cracking of these particles, as shown in Figure 6. Slag penetration into graphite powder reduces SiO₂ and Al₂O₃ content while increasing gas and crystalline phases. These substances react with stabilized zirconia, causing CaO stabilizer dissolution. This subsequently promotes martensitic transformation of zirconia from tetragonal to monoclinic crystal systems, resulting in particle fragmentation and refinement.

Destruction Mechanism of Zirconia Raw Materials

E-mail:info@cxrefractories.com

Tel:+86-371-88888998

Fax:+86-371-88886886

Address:South Tower, Greenland Central Plaza, Zhengzhou, Henan Province, China